The Only AWG Wire Size Chart You’ll Ever Need: A Comprehensive Guide

Navigating the world of electrical wiring can feel like deciphering a secret code. One of the most critical aspects of this code is understanding American Wire Gauge (AWG) sizes. Choosing the right AWG wire size is paramount for safety, efficiency, and preventing potential electrical hazards. This comprehensive guide provides you with the definitive AWG wire size chart and all the essential information you need to make informed decisions for your electrical projects. Forget endless scrolling – this is the only resource you’ll need!

What is AWG and Why Does it Matter?

American Wire Gauge (AWG) is a standardized system used in North America to specify the diameter of electrical wires. The AWG number is inversely proportional to the wire’s diameter; a smaller AWG number indicates a larger wire diameter, and vice versa. Think of it like this: the lower the number, the “beefier” the wire!

Choosing the incorrect AWG wire size can lead to:

- Overheating: Wires carrying excessive current can generate heat, potentially leading to insulation damage, fire, and equipment failure.

- Voltage Drop: Insufficient wire size can result in a significant voltage drop, reducing the effectiveness of connected devices.

- Inefficiency: Under-sized wires increase resistance, wasting energy and increasing operating costs.

- Safety Hazards: Incorrect wiring is a serious safety risk, potentially causing electrocution or fire.

Therefore, selecting the correct AWG wire size is crucial for safety, performance, and longevity of your electrical systems.

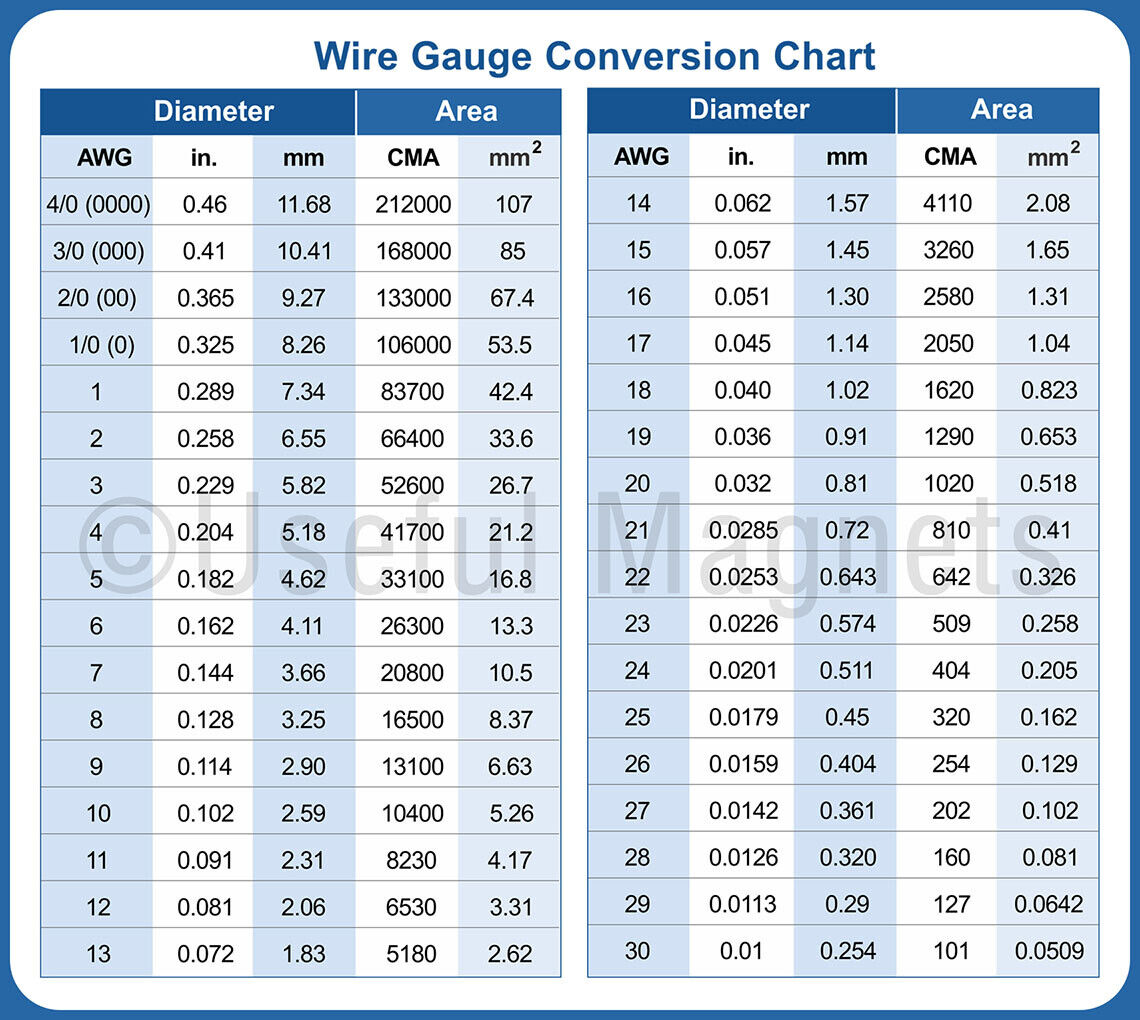

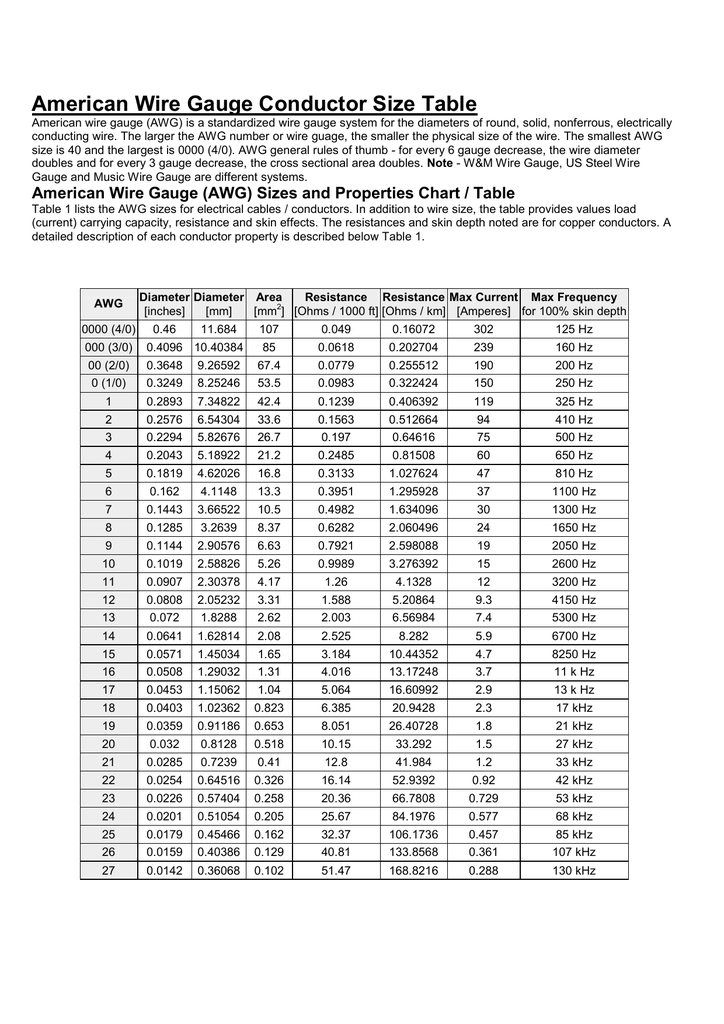

The Ultimate AWG Wire Size Chart

Below is a comprehensive AWG wire size chart, including wire diameter, cross-sectional area, maximum amperage ratings (based on common industry standards), and typical applications. Remember that these amperage ratings are guidelines and can vary based on factors like insulation type, ambient temperature, and installation method. Always consult local electrical codes and regulations.

| AWG Size | Diameter (in) | Diameter (mm) | Circular Mils | Cross-Sectional Area (mm²) | Maximum Amperage (Amps) | Typical Applications |

|---|---|---|---|---|---|---|

| 0000 (4/0) | 0.4600 | 11.68 | 211,600 | 107.21 | 380-445 | High-power applications, welders, large motors |

| 000 (3/0) | 0.4096 | 10.40 | 167,800 | 85.03 | 335-380 | High-power applications, welders, large motors |

| 00 (2/0) | 0.3648 | 9.27 | 133,100 | 67.43 | 290-330 | High-power applications, welders, large motors |

| 0 (1/0) | 0.3249 | 8.25 | 105,500 | 53.47 | 250-280 | High-power applications, welders, large motors |

| 1 | 0.2893 | 7.35 | 83,700 | 42.41 | 220-240 | Large appliances, subpanels |

| 2 | 0.2576 | 6.54 | 66,400 | 33.63 | 190-210 | Large appliances, subpanels |

| 3 | 0.2294 | 5.83 | 52,630 | 26.67 | 165-180 | Large appliances, subpanels |

| 4 | 0.2043 | 5.19 | 41,740 | 21.15 | 145-160 | 240V appliances, main circuits |

| 6 | 0.1620 | 4.11 | 26,250 | 13.30 | 95-110 | 240V appliances, general circuits |

| 8 | 0.1285 | 3.26 | 16,510 | 8.37 | 60-80 | 120V circuits, outlets, lighting |

| 10 | 0.1019 | 2.59 | 10,380 | 5.26 | 30-40 | 120V circuits, outlets, lighting |

| 12 | 0.0808 | 2.05 | 6,530 | 3.31 | 20-25 | 120V circuits, outlets, lighting, general purpose |

| 14 | 0.0641 | 1.63 | 4,110 | 2.08 | 15-20 | 120V circuits, outlets, lighting, general purpose |

| 16 | 0.0508 | 1.29 | 2,580 | 1.31 | 10-15 | Low-voltage circuits, lighting, control circuits |

| 18 | 0.0403 | 1.02 | 1,620 | 0.82 | 7-10 | Low-voltage circuits, lighting, control circuits |

| 20 | 0.0320 | 0.81 | 1,020 | 0.52 | 5-7 | Low-voltage circuits, lighting, control circuits |

| 22 | 0.0253 | 0.64 | 640 | 0.33 | 3-5 | Low-voltage circuits, lighting, control circuits |

Important Considerations when Using the Chart:

- Amperage Ratings: These are approximations. Always verify with your local electrical codes and the manufacturer’s specifications for the specific wire insulation type (e.g., THHN, THW).

- Voltage Drop: Longer wire runs require larger wire sizes to minimize voltage drop.

- Derating: When wires are bundled together or run in enclosed spaces, the ampacity (current-carrying capacity) must be derated (reduced) to prevent overheating.

- Local Codes: Always consult and adhere to your local electrical codes and regulations.

- Insulation Type: Different insulation types have different temperature ratings and ampacity ratings.

How to Choose the Right AWG Wire Size: A Step-by-Step Guide

- Determine the Load: Calculate the total wattage (Watts) or amperage (Amps) of the electrical devices you’ll be powering. (Watts = Volts x Amps)

- Voltage: Identify the voltage of your electrical system (e.g., 120V or 240V).

- Calculate the Amperage: If you know the wattage, divide the wattage by the voltage to find the amperage. (Amps = Watts / Volts)

- Consider the Wire Run Length: Longer wire runs require larger wire sizes to compensate for voltage drop. Use a voltage drop calculator or consult an electrician for assistance.

- Consult the AWG Chart: Use the chart above to select a wire size that can safely handle the calculated amperage. Choose a wire size that exceeds the calculated amperage to provide a safety margin.

- Check Local Codes: Verify that your chosen wire size meets all local electrical codes and regulations.

- Select Wire Type: Choose the appropriate wire type based on the application (e.g., THHN for general use, UF for direct burial).

FAQs About AWG Wire Sizes

1. What is the difference between solid and stranded wire?

- Solid wire is a single, solid conductor. It’s typically used in permanent installations and is easier to work with for short runs.

- Stranded wire is made up of multiple small wires twisted together. It’s more flexible and is preferred for applications where the wire needs to be bent or moved frequently.

2. How do I calculate voltage drop?

Voltage drop can be calculated using the following formula:

- Voltage Drop = (2 * K * I * D) / CM

Where:

- K = Resistivity of copper (12.9 ohms/CM-ft at 20°C)

- I = Current (Amps)

- D = One-way distance of the wire run (feet)

- CM = Circular mils (from the AWG chart)

You can also use online voltage drop calculators for simpler calculations.

3. What does “ampacity” mean?

Ampacity refers to the maximum amount of current a wire can safely carry without exceeding its temperature rating. It’s essentially the current-carrying capacity of the wire.

4. Can I use a larger wire size than required?

Yes, you can generally use a larger wire size than required. However, it’s often unnecessary and can increase costs. Always ensure the overcurrent protection device (fuse or circuit breaker) is appropriately sized for the wire.

5. What is the difference between THHN and THW wire?

- THHN (Thermoplastic High Heat-resistant Nylon coated) is a common wire type suitable for general use in dry locations and can also be used in wet locations.

- THW (Thermoplastic Heat-resistant Water-resistant) is also a common type and is rated for wet locations. Both are commonly used in residential and commercial wiring. Check local codes for specific requirements.

Conclusion: Wiring with Confidence

Understanding AWG wire sizes is fundamental to any electrical project. This comprehensive guide provides you with the tools and knowledge to choose the correct wire size, ensuring safety and optimal performance. By using the AWG wire size chart, following the step-by-step guide, and consulting local codes, you can confidently navigate the world of electrical wiring. Remember to always prioritize safety and, when in doubt, consult a qualified electrician.